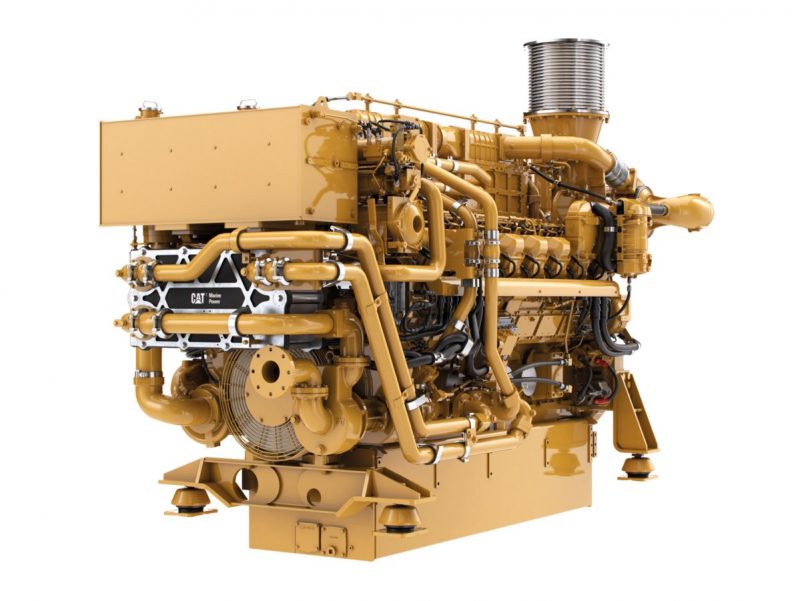

3516

Overview

The 3516 marine auxiliary engine is now available in a wide range of ratings that meet U.S. EPA Tier 4 Final and IMO III marine emissions regulations. As the commercial marine industry adjusts their operations to meet EPA Tier 4 Final and IMO III emissions standards, Caterpillar Marine has introduced a solution built to maximize performance while meeting regulations. Caterpillar's combination of a fuel-efficiency-optimized engine and a selective catalytic reduction (SCR) after treatment system is a solution that not only reduces NOx emissions, but can also lower a customer's owning and operating costs in the process.

Image shown may not reflect actual package.

Documents & Links

No downloads available for this product.