Dynamic Solutions: Prime and Standby Power

The Client: Thiess’ Mount Owen Open-Cut Coal Mine

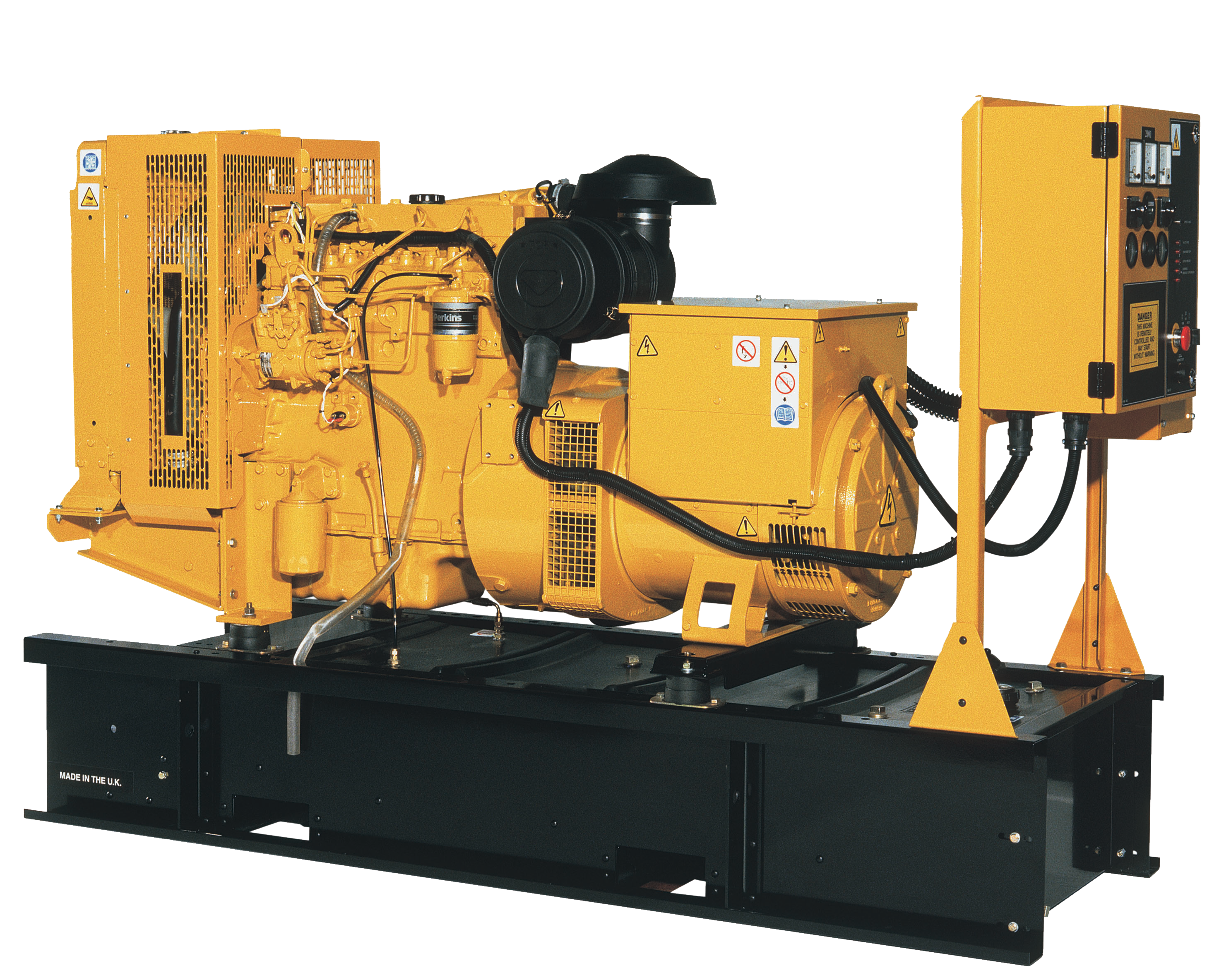

A compact 44.5 kVA generator for a mobile service vehicle – designed to perform on-site servicing of mining equipment.

The Background

With more than 70 years experience in all areas of mining, including coal, open-cut and underground, the Thiess group is regarded as a world class mining service provider mining in excess of 60 million tonnes of coal per year.

Currently operating over 15 mines Thiess is one of the largest coal miners in the Australasian region with a plant fleet valued in excess of $1.2 billion, which moves more than 2 million tonnes of material daily.

So when it comes to operating efficiencies Thiess is an innovative market leader, continually fine tuning their operations to maximise productivity.

The Requirement

Recently Thiess’ Mount Owen open-cut coalmine commissioned Starline Motor Bodies to build a new concept service vehicle to enable their engineers to perform on-site service work on their fleet of mining equipment.

But when an error in the generator set specifications was detected during the vehicle’s assembly Thiess needed the assistance of a supplier who’d think outside the box to get the project back on track – so they turned to Energy Power Systems Australia’s (EPSA) Electric Power division, which is also responsible for sales and marketing of the Olympian Generator product range.

EPSA’s Electric Power division has established a reputation for solving the toughest of challenges and according to Olympian NSW Sales Representative, Ken Fackler, Thiess’ predicament called for some re-engineering miracles.

“Put simply, the original specs for the onboard generator set were underestimated for the load of the welding gear, lighting equipment and a compressor. “Inline with the specifications the chassis was built to accommodate a 22 kVA generator set between the cab and the body, but the compressor ordered was a new model that featured variable speed drive which plays hell with the gen-sets harmonics, rendering the 22 kVA unit too small for the task.

“As the variable speed drive oversight was made by the original generator set supplier Thiess turned to us to get them out of the hole, as they’d had plenty of experience with CAT product and our extensive support network”, Ken said

The Solution

After running the Caterpillar Generator SpecSize software programme, Ken recommended a 44 kVA Olympian GEP 44-5 generator set. According to Ken, at first those involved in building the vehicle didn’t believe that they required this level of power, but with SpecSize we could prove our recommendations beyond doubt.

“The Olympian range of stand-by and prime power generator sets are innovative and robust designs that have led to the Olympian product range being recognised for reliability and dependability worldwide, as well as meeting the stringent European standards for exhaust and noise emissions – making them a very eco-friendly package.

“Once the Olympian GEP 44.5 was agreed upon we set about re-engineering the standard configured unit in order to fit it into the available space.

“The modifications undertaken were extensive, including moving all the integrated electronic controls to the end of the body and incorporating a roller shutter into the sound attenuated enclosure for access.

“And due the stringent mining regulations the modified unit had to be re-wired, with all the wiring harnesses enclosed in sealed conduit, and then the isolation switches and circuit breakers had to be beefed up considerably to cope with the extra power.

“In the end it was a massive job, but we got it done and the client is extremely satisfied, which at the end of the day is what it’s all about”, Ken added.

The Results

According to Bruce Robinson, a Thiess Electrical Engineer involved the later stages of the project, the technical support received from Ken and his team at Energy Power Systems Australia to sort out the problems was excellent.

“Once we figured out what the load was going to be the CAT option was a pretty convenient one for us, as they are already involved on-the-ground here supporting their other equipment.

“The service vehicle has been operational for nearly 12 months now without any problems”, Bruce said.

“Olympian generator sets are manufactured at Caterpillar’s ISO 9001 certified facility in the UK and represent a lower entry level product range that boasts CAT performance with exceptional fuel efficiency and proven

performance for standby and prime power applications up to 550 kVA.

“Available for use with diesel fuel, propane, or natural gas, Olympian generator sets deliver dependable, clean economical power even in the most demanding conditions and can be configured to meet the needs of any application, all backed by Caterpillar’s extensive nationwide support network”, Kim said.