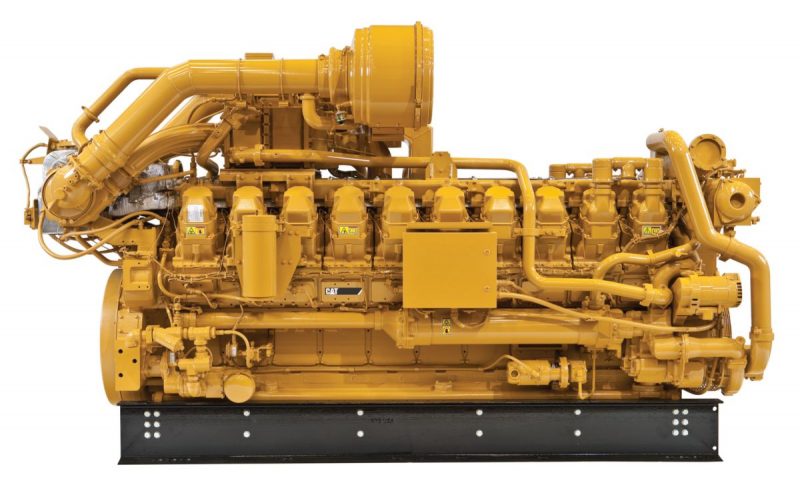

G3520B

Overview

The line of G3500B engines brings versatility, uptime, and low operating cost to your gas compression operation. They deliver the lowest engine-out emissions in the industry without sacrificing performance. Ideal applications for G3500B engines include gas lift, gas gathering, and wellhead gas compression. Cat G3520B gas engine. Ratings: 1104-1286 bkW (1480-1725 bhp) @ 1200-1400 rpm are NSPS site compliant capable.

Image shown may not reflect actual package.

Documents & Links

No downloads available for this product.