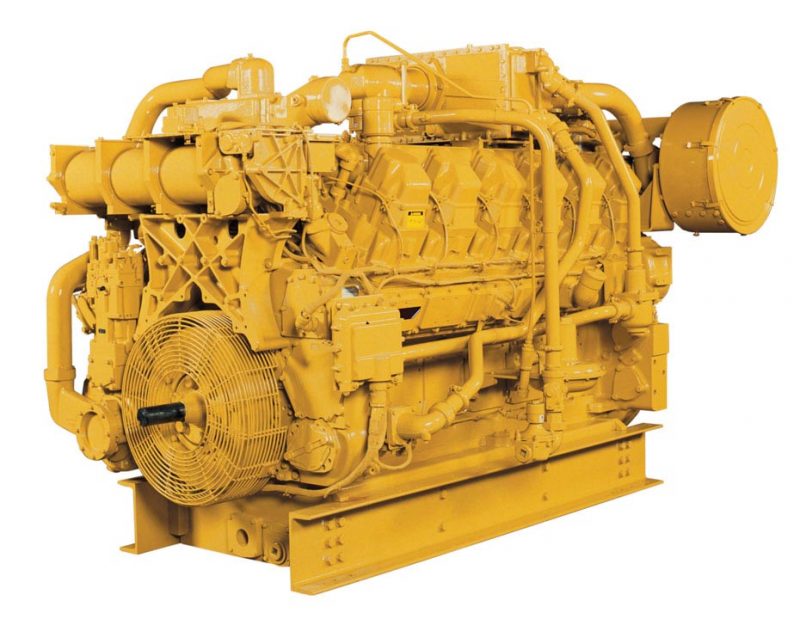

G3512

Overview

The Cat® G3512 Industrial Gas Engines are offered in the following ratings: 589-642 bkW (790-860 bhp) @ 1200 rpm and 749-772 bkW (1004-1035 bhp) @ 1400 rpm. These ratings are NSPS site compliant capable with customer-supplied after treatment. For specific emission information, please consult your local Cat Dealer.