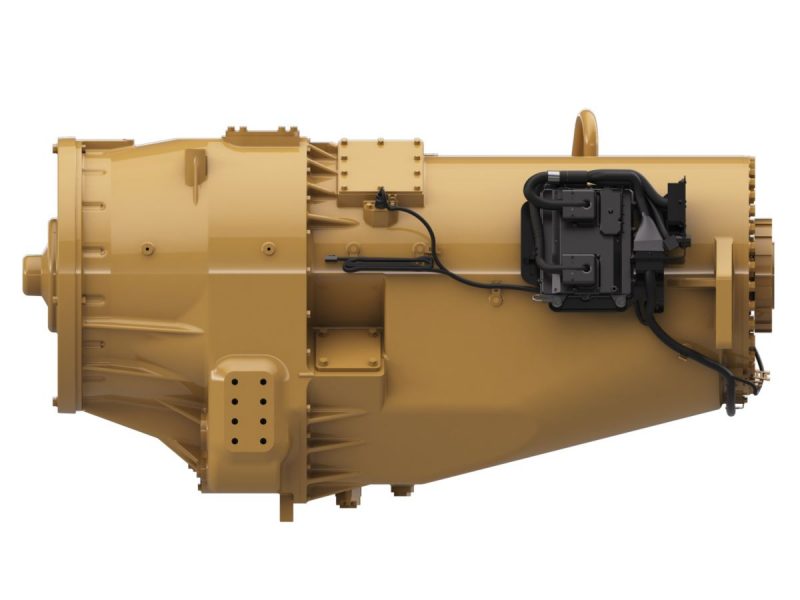

CX48-P2300

Your operation depends on the power driving it. And your transmission is as crucial to your power solution as the engine. Cat transmissions are proven in the oil and gas industry and widely known for their exceptional power, leading durability, ease of operation, and shifting options. Ideal applications for Cat CX48-P2300 transmissions include pressure pumping, kill mud pumps, coil tubing pump support, nitrogen units, and acidizing units. CX48-P2300 transmissions are optimized for use with Cat 3512B and 3512C engines. Cat transmissions are backed by the worldwide network of Cat dealers ready to support your operation with technical support, service, parts, and warranty. Cat CX48-P2300 oilfield transmission. Gross input power: 1715 bkW (2300 bhp).