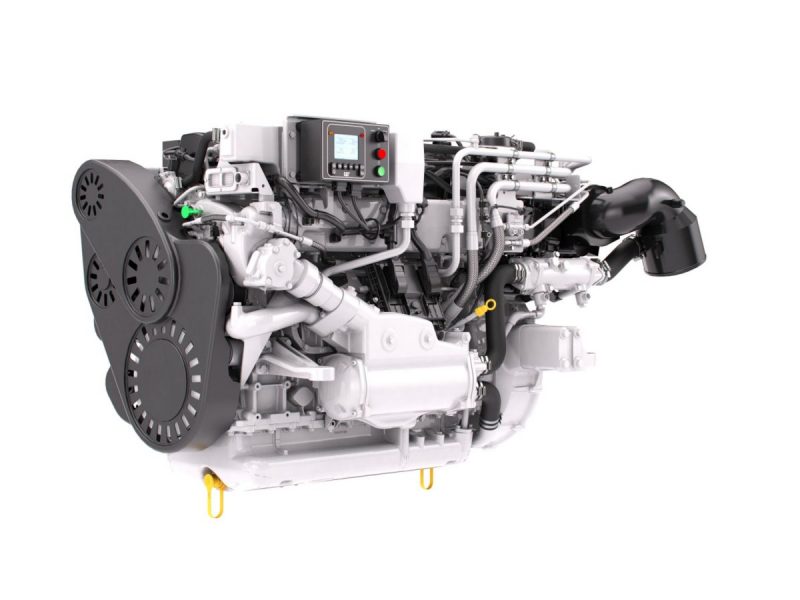

C8.7 Recreational Engine

Overview

The C8.7's sophisticated fuel delivery system allows the use of a radial, belt-driven supercharger in addition to the conventional turbocharger; this feature eliminates smoke and reduces lugging, while delivering phenomenal low-end torque and impressive fuel economy. Advancements in second-generation common rail fuel injection systems paired with an innovative air management system allow the compact C8.7 to develop an impressive 650 mhp @ 2300 rpm while meeting EPA Tier 3 Commercial, EPA Tier 3 Recreational, IMO II, and EU Stage IIIA (EU IW) emissions standards.

Image shown may not reflect actual package.

Documents & Links

No downloads available for this product.