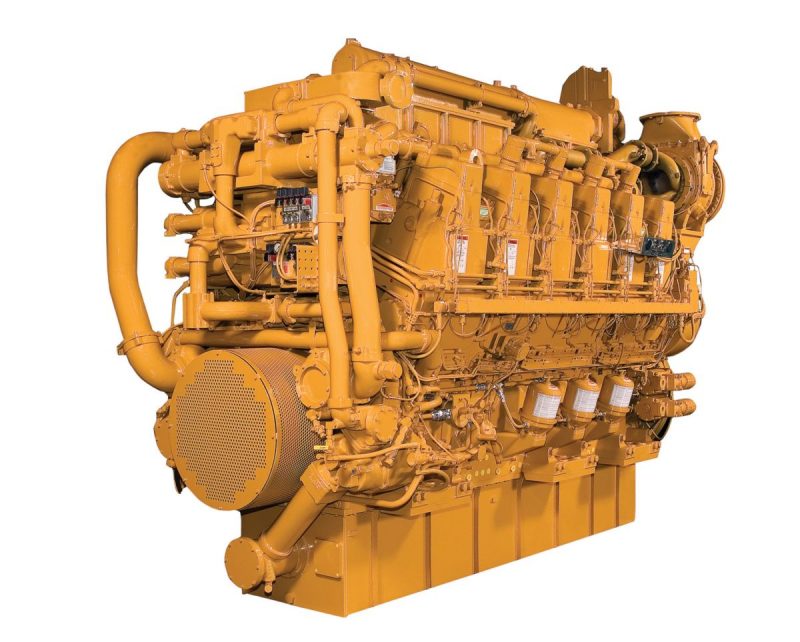

C280

Overview

Caterpillar is pleased to offer the C280 engine line. Cat C280 Marine Auxiliary Engines are available in 6, 8, 12, 16 and 18 cylinder configurations. The core components are the same as the existing C280, including the latest in EUI fuel system capabilities and state-of-the-art ADEM™ A3 Electronic Control Unit (ECU) features. Caterpillar® products continue to deliver more available power while delivering outstanding fuel efficiency. You can also count on long maintenance intervals and worldwide Caterpillar parts and service availability.

Image shown may not reflect actual package.

Documents & Links

No downloads available for this product.